Jason Deveau, Application Technology Specialist, Ontario Ministry of Agriculture, Food and Rural Affairs

For sprayer operators to reduce the potential for pesticide drift, they must be situationally aware, willing to make operational changes, and they must possess a basic understanding of why drift happens – and that means physics. Sir Isaac Newton was 23 years old when he postulated, “An object in motion remains in motion at constant speed and in a straight line unless acted on by an unbalanced force.” He was telling us that the more we can control or compensate for the forces that influence a droplet’s movement, the more likely we can direct where it will end up. Here’s a run-down on some of those forces and what operators can do about them.

Droplet size

Coarser droplets have more mass, which means they have more inertia; they are less prone to deflection by wind, more prone to deflection by gravity, and therefore most likely to travel ballistically (e.g. like a cannonball). Coarser droplets also have smaller surface-to-volume ratios. This means they resist evaporation on hot and dry days, staying on course and remaining wet longer on target surfaces (often associated with better product performance). Switching to nozzles that produce a coarser spray will reduce drift potential but may also negatively affect coverage by reducing droplet count, canopy penetration and retention. Operators should understand how much coverage is required for whatever they are spraying and be prepared to switch to a coarser spray as the situation dictates.

Distance to target

The longer a droplet remains in the air, the more opportunity for outside forces to affect its trajectory. Increasing pressure can increase droplet velocity, but it also increases spray volume (on non-PWM sprayers), reduces the average droplet size, and does not have an appreciable influence on the finer, more drift-prone droplets. A far better approach is to bring nozzles as close to the target as practicably possible. In other words, horizontal boom sprayer operators should lower the boom and airblast sprayer operators should invest in towers, adjust deflectors, and consider pruning or hedging practices.

Travel speed

Consider the following metaphor. If you dropped a ball from the window of a moving car, it would follow a downward/forward vector. The faster the car, the greater the forward component. How would wind play a role in this? Windspeed and travel speed are additive, which means that driving into a headwind adds travel speed to wind speed, increasing the chance of deflecting the ball – or in the case of a sprayer, displacing droplets from the swath and leaving them hanging in the air.

Those suspended droplets are also subject to turbulent eddies created by the sprayer chassis and wheels that swirl in unpredictable ways and can propel them upwards, increasing their distance to target. Increased travel speed also tends to amplify boom yaw, necessitating higher booms to prevent impacts and increasing a droplet’s distance to target. Operators sometimes resist slowing down because of the negative effect on their work rate. However, this can be offset by more efficient filling and cleaning practices and/or from an improved yield arising from better coverage uniformity. Slowing down works.

Wind and atmospheric stability

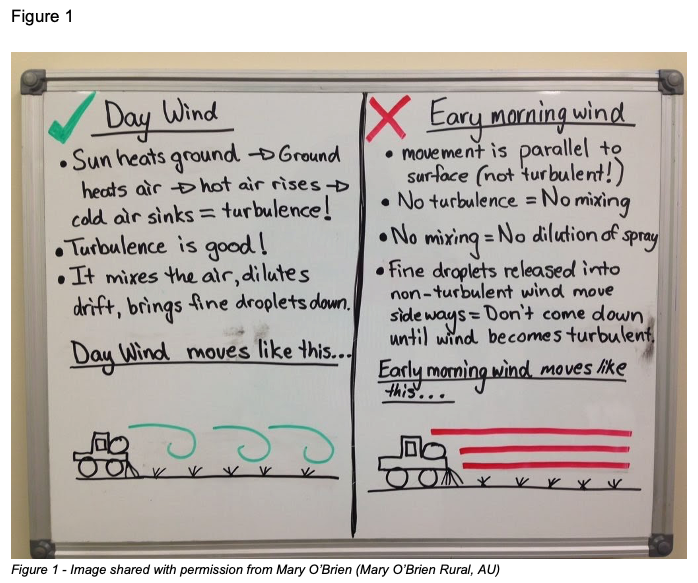

Spray droplets can be displaced from the swath by the wind. The distance they drift depends on apparent wind speed and droplet size. On moderately (not excessively) windy days, operators can predict the direction spray might drift and plan accordingly when there are sensitive areas to protect. If the options are available, wind can be blocked by shrouds or outcompeted by air assist. However, simply reducing the distance to target and increasing droplet size can be effective practices. In any case, some proportion of the spray will always remain airborne, and its fate will depend on atmospheric stability. (See Figure 1).

On warm, sunny days, turbulence will ground airborne droplets or dilute them in a process called atmospheric mixing. As finer droplets gain altitude and spread out, the odds of downwind deposition are reduced. On the other hand, calm conditions tend to coincide with a condition known as a temperature inversion, where the air is warmer with elevation instead of colder, as is typical. In such a situation, thermal convection will not occur, and finer droplets can hang in the air for long periods of time. This makes them susceptible to light, lateral winds that can carry them long distances or downhill, according to topography. Inversions are more likely to occur between evening and early morning in humid and cloudless conditions. Inversions are of particular concern when applying volatile products that can off-gas into the air long after they are applied. Operators should avoid night-spraying practices that might coincide with an inversion.

Understanding the physics of how droplet size, travel speed, distance to target, and environmental conditions affect drift potential empowers a sprayer operator to act accordingly. This sometimes requires compromise, and ultimately (however inconveniently), an operator may have to halt spraying until conditions improve.

For more information on spraying best practices, go to www.sprayers101.com and enter the keyword “drift” in the search field.

Dr. Jason Deveau is the application technology specialist with the Ministry of Agriculture, Food and Rural Affairs.

Additional Resources

- OMAFRA Fact sheet – Pesticide Drift from Ground Applications

- Sprayers 101 for resources on sprayer cleaning and the dangers of temperature inversions.

- OFA Information Sheet – You Suspect Herbicide Drift – Now What?